Introduction

In today’s rapidly evolving business landscape, digital transformation has emerged as a critical imperative for organizations seeking to remain competitive and relevant. The fusion of technology with traditional processes promises increased efficiency, improved customer experiences, and new avenues for growth. However, embarking on this journey is not without its challenges. In this article, we will explore strategies for successful digital transformation, helping you navigate the complex terrain of

technological change and emerge as a digitally empowered and future-ready enterprise.

As-Is, To-Be, and Gap Analysis in Business Improvement

Business improvement often begins with a thorough analysis of current processes, identifying areas for enhancement, and envisioning a more efficient future state. This process involves three key stages: As-Is analysis, To-Be analysis, and Gap analysis. Let’s delve into each of these concepts:

1. As-Is Analysis:

Definition: As-Is analysis, also known as current state analysis, involves a comprehensive examination and documentation of an organization’s existing processes, systems, and workflows.

Purpose: The primary goal of As-Is analysis is to gain a deep understanding of how things currently operate within the organization. This includes mapping out processes, documenting steps, interactions, and workflows, and capturing data on performance metrics.

Methodology:

- Process Mapping: Creating visual representations (e.g., flowcharts or BPMN diagrams) of current processes to illustrate how tasks flow and how various stakeholders interact.

- Data Collection: Gathering quantitative and qualitative data related to the processes, such as cycle times, error rates, and resource utilization.

- Stakeholder Interviews: Engaging with individuals involved in the process to gather insights, feedback, and pain points.

2. To-Be Analysis:

Definition: To-Be analysis, or future state analysis, involves envisioning and designing an improved version of the existing processes, systems, or workflows.

Purpose: The objective of To-Be analysis is to create a vision of how processes should ideally function in the future. This includes identifying opportunities for efficiency, effectiveness, and alignment with organizational goals.

Methodology:

- Process Redesign: Reimagining and redesigning workflows to eliminate bottlenecks, reduce waste, and optimize resource utilization.

- Technology Integration: Identifying and implementing technology solutions that can enhance and automate processes.

- Performance Metrics: Defining key performance indicators (KPIs) to measure the success of the new process.

- Change Management: Planning how the transition from the As-Is state to the To-Be state will be managed, including training, communication, and stakeholder buy-in.

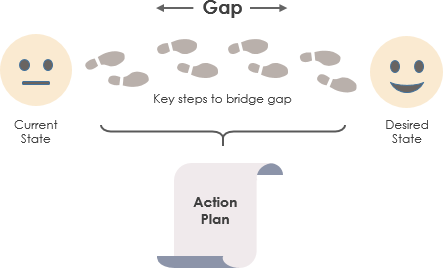

3. Gap Analysis:

Definition: Gap analysis involves comparing the As-Is and To-Be states to identify discrepancies, differences, or “gaps” between the current and desired future states.

Purpose: Gap analysis serves as a critical step to understand what needs to change and where opportunities for improvement exist. It provides a roadmap for bridging the divide between the As-Is and To-Be states.

Methodology:

- Comparison: Carefully assess and compare the documented As-Is state with the envisioned To-Be state.

- Gap Identification: Identify specific areas where differences or gaps exist, such as process inefficiencies, technology shortcomings, or skill deficiencies.

- Prioritization: Prioritize the identified gaps based on their impact and feasibility for improvement.

- Action Plan: Develop a detailed action plan to address and close the identified gaps, outlining the steps, resources, and timelines required.

As-Is, To-Be, and Gap analyses are essential components of business improvement efforts. They provide organizations with a structured approach to evaluate their current operations, design more efficient and effective future states, and bridge the divide between the two. By implementing the insights gained through these analyses, businesses can enhance their processes, drive innovation, and ultimately achieve their strategic objectives.

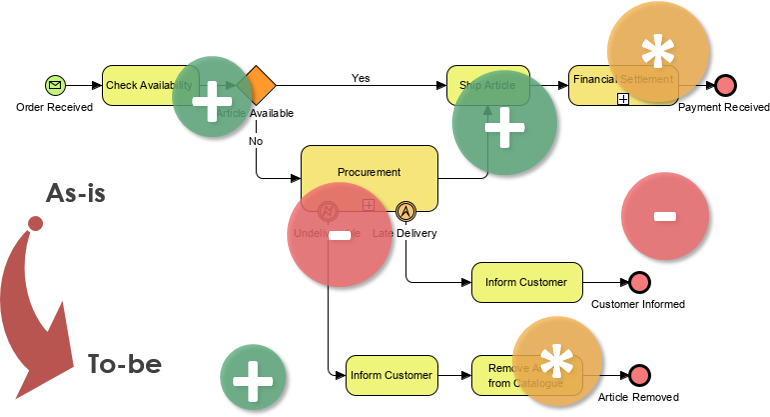

Example: Inventory System (as-is / To-be, Gap)

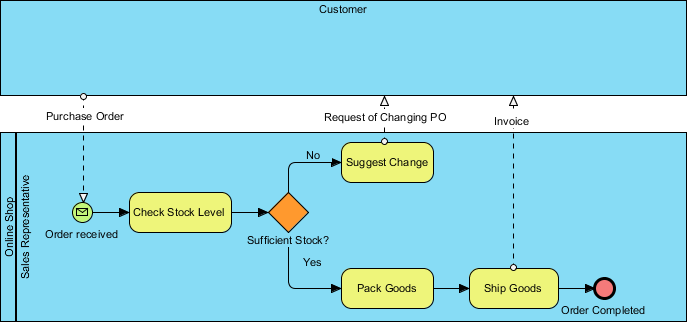

This problem involves an online shop that sells goods and its current order fulfillment process. The process starts when a sales representative receives a purchase order from a customer and involves checking the stock level, packing the items if they are in stock, and shipping them along with an invoice. If there is insufficient stock, the sales representative suggests amending the purchase order. This is represented in an As-is BPMN (Business Process Model and Notation) diagram.

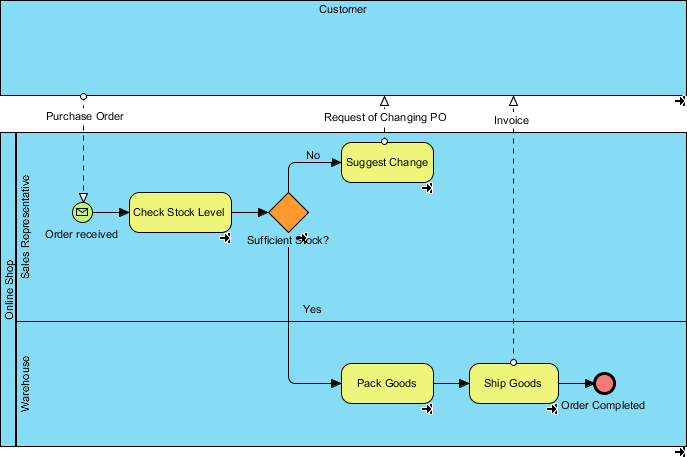

Now, there’s a need to enhance this As-is process with a To-be process, as the business has grown, and they are introducing a warehouse to improve stock management and ease the workload of sales representatives. Here’s how you can elaborate on this transition from the As-is to the To-be process:

As-is Process:

- Customer Order Receipt: The process begins when a sales representative receives a purchase order from a customer through the online shop’s platform.

- Stock Checking: The sales representative checks the stock level of each item requested in the purchase order. This involves manually reviewing the inventory records or using an inventory management system.

- Inventory Assessment: If there is enough stock on hand to fulfill the order, the sales representative proceeds to the next step. Otherwise, if there is insufficient stock, they inform the customer and suggest amending the purchase order.

- Packing: If there is enough stock, the sales representative packs the ordered items for shipment. This step may involve selecting appropriate packaging materials and ensuring that the items are adequately protected.

- Shipping and Invoicing: The packed items are shipped to the customer, and an invoice is generated and sent to them.

To-be Process:

With the introduction of a warehouse and the aim to improve inventory management and relieve the workload of sales representatives, several changes are made to the process:

- Customer Order Receipt: This step remains the same as in the As-is process, with customers placing orders through the online shop.

- Inventory Management: Instead of the sales representative manually checking stock levels, the process now includes an automated inventory management system integrated with the warehouse. This system continuously monitors stock levels in real-time.

- Warehouse Allocation: When a purchase order is received, the system checks the stock availability in the warehouse. If sufficient stock is available, it initiates the packing process; otherwise, it prompts for order amendments.

- Packing and Shipping: The packing process is still executed, but it is now initiated based on the warehouse’s stock status. Packaging and shipping are streamlined, and the entire process is more efficient.

- Invoicing: Invoicing remains similar to the As-is process, with invoices generated and sent to customers.

Benefits of the To-be Process:

- Efficiency: Automation and real-time inventory management make the process more efficient, reducing delays caused by stock checking.

- Resource Relief: Sales representatives no longer need to manually check stock levels, allowing them to focus on customer interactions and order management.

- Inventory Accuracy: The warehouse integration ensures better control and accuracy in inventory management, reducing the chances of overstocking or stockouts.

- Customer Satisfaction: Faster order processing and fewer order amendments lead to improved customer satisfaction.

Transitioning from the As-is to the To-be process involves automating inventory management and integrating a warehouse to improve efficiency, reduce errors, and enhance the overall customer experience.

Conclusion: Bridging the Path to Business Excellence

In the realm of business improvement, the journey from the current state to a future state of excellence begins with a profound understanding of where you are, where you want to be, and how to get there. The trifecta of As-Is, To-Be, and Gap analyses serves as the compass, map, and guide along this transformative path.

As-Is analysis lays bare the inner workings of your organization, unveiling the intricacies of your processes and systems. It is a snapshot in time, capturing the present with precision and honesty. To-Be analysis, on the other hand, is the visionary’s canvas where you paint the picture of a better tomorrow. It’s where innovation and optimization take root, creating the blueprint for your business’s evolution.

But it is Gap analysis that bridges the gap between the present and the future. It is the place where aspirations meet reality, where strategies meet execution, and where plans meet action. Gap analysis takes the insights gleaned from As-Is and To-Be analyses and transforms them into actionable steps, setting the course for continuous improvement.

In this triad of analyses, we find not just a methodology but a philosophy. It is a commitment to growth, adaptability, and staying ahead in a dynamic business landscape. It is the recognition that complacency breeds stagnation, while change fuels progress.

As you embark on your own journey of business improvement, remember that these analyses are not endpoints but waypoints. They are tools for transformation, guiding you toward operational excellence, enhanced customer experiences, and lasting success.

So, embrace the power of As-Is, To-Be, and Gap analyses. Embrace the journey from understanding to innovation to execution. By doing so, you’re not just improving your business; you’re shaping its future, one insightful analysis at a time.