Unlocking Process Optimization: The Importance of Current State/Future State Analysis

Businesses and organizations are constantly looking for ways to improve their operations, whether it’s increasing efficiency, reducing costs, or improving the customer experience. One way to achieve these goals is by performing a Current State/Future State analysis. This type of analysis is a powerful tool that allows organizations to identify and map their current processes, as well as define and plan for future processes that will help them achieve their desired goals.

What is Current State/Future State Analysis?

Current State/Future State analysis is a process that involves mapping out the current state of a business process, identifying its strengths and weaknesses, and then designing a future state that addresses those weaknesses and optimizes the process for better results. This type of analysis is commonly used in business process improvement initiatives, such as Lean Six Sigma and Agile methodologies.

- The Current State of a process is the existing state of the process, which is documented and analyzed to understand how it works and identify opportunities for improvement. This includes identifying inefficiencies, bottlenecks, waste, and other issues that prevent the process from working optimally.

- The Future State, on the other hand, is the desired state of the process that the organization wants to achieve. It is designed to address the issues identified in the Current State analysis and optimize the process for improved performance. The Future State typically includes process changes, new technologies, and other improvements that are necessary to achieve the desired results.

Why is Current State/Future State Analysis Important?

Current State/Future State analysis is an essential tool for process improvement initiatives, as it provides a clear understanding of the current state of a process and identifies opportunities for improvement. By mapping out the current state of a process, organizations can identify inefficiencies and bottlenecks that are preventing the process from working optimally. This information can then be used to design a future state that addresses these issues and optimizes the process for better performance.

Current State/Future State analysis also helps organizations to develop a roadmap for process improvement. By mapping out the current state and future state, organizations can identify the steps required to achieve the desired results. This roadmap helps to guide the implementation of process improvements, ensuring that they are carried out in a structured and logical manner.

Another benefit of Current State/Future State analysis is that it helps to align stakeholders and teams around a common goal. By mapping out the future state, organizations can clearly communicate their vision for the process, and stakeholders can provide input and feedback to ensure that the future state is achievable and aligned with organizational goals.

Performing a Current State/Future State analysis

Performing a Current State/Future State analysis requires a structured approach that involves several steps. Here are the steps to follow for conducting a successful analysis:

- Identify the process to analyze: The first step is to identify the process to analyze. It is important to select a process that has a significant impact on the organization and aligns with the organization’s goals.

- Map the Current State: Once the process has been identified, the next step is to map out the Current State of the process. This involves documenting how the process works, including all the inputs, activities, and outputs. This information can be gathered through interviews with process owners, observation of the process, and data collection.

- Analyze the Current State: Once the Current State has been mapped out, the next step is to analyze it to identify inefficiencies, bottlenecks, and other issues that prevent the process from working optimally. This analysis can be done using process mapping tools, such as flowcharts and value stream maps, and data analysis techniques, such as statistical process control.

- Define the Future State: Based on the analysis of the Current State, the next step is to define the Future State of the process. This involves designing a process that addresses the issues identified in the Current State analysis and optimizes the process for better performance. The Future State should be aligned with the organization’s goals and be achievable within a reasonable timeframe.

- Develop a Roadmap: Once the Future State has been defined, the next step is to develop a roadmap for implementing the changes required to achieve the Future State. The roadmap should include the steps required to implement the changes, the resources needed, and the timeline for implementation.

- Implement the Changes: The final step is to implement the changes required to achieve the Future State. This involves putting the roadmap into action, including training employees, implementing new technologies, and monitoring the process to ensure that the changes are effective.

By following these steps, organizations can perform a successful Current State/Future State analysis and achieve significant improvements in their processes. It is important to note that this is an iterative process, and organizations may need to repeat some of the steps to refine the process further.

Example

Problem: A company that manufactures and distributes products to retailers is experiencing a high rate of customer returns and complaints due to incorrect or damaged products being shipped to customers. This has resulted in a loss of revenue and damage to the company’s reputation. The company wants to reduce the rate of returns and complaints and improve customer satisfaction.

Solution: The company can perform a Current State/Future State analysis to identify the root cause of the problem and design a future state that addresses the issues. The steps for the analysis could be as follows:

Current State Analysis

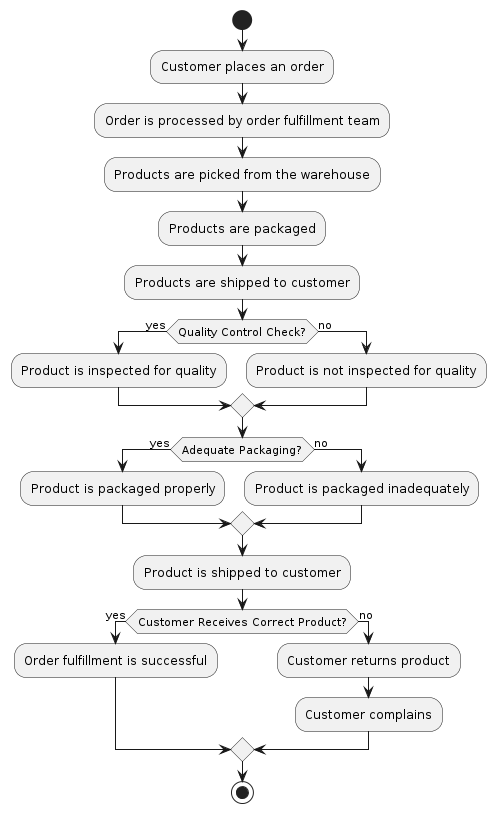

The current state of the Order Fulfillment process is characterized by a high rate of customer returns and complaints due to incorrect or damaged products being shipped. The process begins when a customer places an order through the company’s website. The order is then processed by the company’s order fulfillment team, who are responsible for picking the products from the warehouse, packaging them, and shipping them to the customer.

However, the current process lacks proper quality control checks and packaging materials. As a result, many products are shipped without being inspected for quality and packaged inadequately, leading to damage or incorrect items being shipped to customers. This has resulted in a high rate of customer returns and complaints, leading to a loss of revenue and damage to the company’s reputation.

To address these issues, the company has decided to conduct a Current State/Future State analysis of the Order Fulfillment process. The objective of the analysis is to identify the root causes of the issues and develop a plan to improve the process, reduce the rate of customer returns and complaints, and enhance customer satisfaction.

Here’s an example of a completed template based on a Current State/Future State analysis:

Step 1: Identify the Process to Analyze Process Name:

Order Fulfillment Objective of the Analysis:

-

- Reduce rate of customer returns and complaints due to incorrect or damaged products being shipped to customers.

Step 2: Map the Current State Input:

Customer Order Activity:

-

- Pick products from warehouse,

- Package the products, and

- Ship the products

Output:

-

- Shipped Products Tools Used: Process Flow Diagram

Step 3: Analyze the Current State Issues Identified:

- High rate of incorrect and damaged products being shipped,

- resulting in customer returns and complaints.

Root Causes:

-

- Lack of quality control checks and inadequate packaging materials.

Process Performance Metrics:

-

- Rate of customer returns and complaints,

- order processing time, and

- cost per order.

Step 4: Define the Future State Proposed Changes:

- Implement quality control checks at each stage of the order fulfillment process,

- upgrade packaging materials, and provide additional training for employees.

Expected Improvements:

-

- Reduce rate of customer returns and complaints by 50%,

- improve order processing time by 20%, and

- decrease cost per order by 10%. Alignment with Organizational

Goals:

-

- Improve customer satisfaction,

- increase revenue, and

- enhance the company’s reputation.

Here’s a table summarizing the Current State, Target State, and Gap for the Order Fulfillment process:

| Aspect | Current State | Target State | Gap |

|---|---|---|---|

| Quality Control | No quality control checks | Quality control checks for all products | Large Gap |

| Packaging Materials | Inadequate packaging materials | Adequate packaging materials | Large Gap |

| Customer Feedback | No customer feedback mechanism | Customer feedback mechanism established | Large Gap |

| Performance Metrics | No performance metrics | Performance metrics established | Large Gap |

Step 5: Develop a Roadmap Implementation Steps:

- Identify quality control checkpoints,

- source and implement new packaging materials,

- conduct employee training, and monitor process performance.

Resources Required:

-

- Quality control tools and equipment,

- new packaging materials, and employee training resources.

- Timeline for Implementation:

6 months.

-

- Training Needs:

- Training on quality control procedures and

- new packaging materials.

Step 6: Implement the Changes Actions Taken:

- Implemented quality control checks,

- upgraded packaging materials,

- provided employee training, and

- monitored process performance.

Outcomes Achieved:

-

- Reduced rate of customer returns and complaints by 60%,

- improved order processing time by 25%, and

- decreased cost per order by 15%.

- Lessons Learned:

- Importance of continuous monitoring and improvement,

- the value of involving employees in the analysis and implementation process.

By using this template, the organization can document the Current State/Future State analysis process, track progress, and ensure that the analysis is aligned with organizational goals.

Summarize the Analysis into an Action Plan

Here’s an action plan in table format based on the analysis above:

| Aspect | Action | Responsible Party | Timeline |

|---|---|---|---|

| Quality Control | Hire additional staff for quality control checks | HR Department | Within 2 weeks |

| Quality Control | Train staff on quality control procedures | Operations Manager | Within 4 weeks |

| Quality Control | Implement quality control checks for all products | Operations Manager | Within 6 weeks |

| Packaging Materials | Research and source adequate packaging materials | Purchasing Department | Within 4 weeks |

| Packaging Materials | Train staff on proper use of packaging materials | Operations Manager | Within 6 weeks |

| Customer Feedback | Establish customer feedback mechanism | Marketing Department | Within 4 weeks |

| Customer Feedback | Train staff on customer feedback procedures | Marketing Department | Within 6 weeks |

| Performance Metrics | Establish key performance indicators (KPIs) | Operations Manager | Within 2 weeks |

| Performance Metrics | Set up systems to measure KPIs | IT Department | Within 4 weeks |

| Performance Metrics | Regularly review KPIs and adjust processes as needed | Operations Manager | Ongoing |

This action plan outlines specific actions that need to be taken to address the gaps identified in the analysis. It also assigns responsibility for each action and sets a timeline for completion. By following this action plan, the company can work towards achieving the Target State for the Order Fulfillment process and improving the overall performance of the process.

Conclusion

Current State/Future State analysis is a powerful tool that allows organizations to identify inefficiencies and bottlenecks in their processes and design a future state that optimizes the process for improved performance. This analysis is an essential part of process improvement initiatives, and it helps organizations to develop a roadmap for improvement and align stakeholders around a common goal.

To perform a successful Current State/Future State analysis, it is essential to have a clear understanding of the existing process, its strengths and weaknesses, and the desired outcome. This requires a structured and systematic approach, including process mapping, data collection, analysis, and stakeholder engagement. By following this approach, organizations can achieve significant improvements in their processes and achieve their desired goals.